公司介绍

-

常州大有自动化系统有限公司(MoveWeigh Automation System Co., Ltd)成立于2013年,工厂位于常州市新北区高新技术开发区,专业制造各种动态高精度在线称重设备。

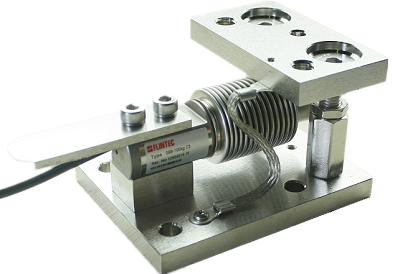

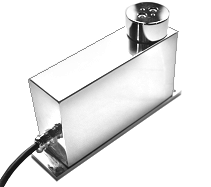

公司由全球优质称重品牌及纳斯达克上市公司资深产品专家创建,主要人员均有15年以上丰富的行业经验,并在不断发展壮大中吸收各种专业技术人才。公司秉承先进的质量管控体系和客户服务理念,在医药、食品、化工、水产品、工业制造、电子、五金、橡胶等多个行业。重点开发动态在线称重领域,同时向全球客户及合作伙伴提供高精度称重设备及解决方案,包括称重传感器、数字称重模块、仪表、台秤、平台秤、云称重软件、防错精益配料系统、在线称重系统等高精度、自动化的在线称重配套,可以和各种装盒机、贴标机、装箱机结合,对每一个产品实时检测重量,确保产品不缺件不缺粒100%合格,对不合格产品直接剔除。为客户提高工作效率及品质,增添质量管控的便利,得到了客户的赞誉。